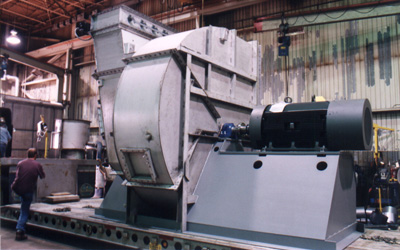

About

Northern Blower Inc.

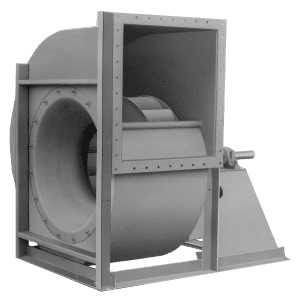

Northern Blower Inc. has been delivering custom industrial fan solutions to customers worldwide since our founding in 1959. We strive to understand your fan application and are capable of designing and manufacturing your optimum fan. From specialized material and critical application small horsepower units to large induced draft fans for cement and power plants; whatever your project demands, we are prepared to deliver.